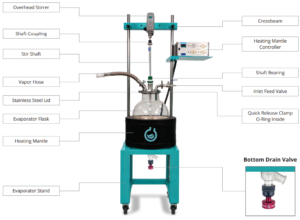

Rotary Evaporator EcoChyll X5 from Ecodyst

For many years, rotary evaporators (rotovaps) have been a standard in laboratories and industries that perform chemistry, such as laboratories in the pharmaceutical, academic, government, chemical, life sciences, food & beverage, cleantech, materials, environmental and cannabis sectors. Rotovaps consist of a heating fluid bath, rotating motor, evaporating flask, receiving flask, vacuum source, and condenser. The conventional rotovap condenser requires an external source of cooling material such as dry ice, liquid nitrogen, water or glycol. Glycol requires additional recirculating chiller equipment. Using a proprietary and innovative self-cooling technology, Ecodyst has revolutionized the rotovap to be more efficient, to have a smaller footprint, to have greater output, and to be less expensive to operate. The modern smart self-cooling technology from Ecodyst boosts productivity and prevents productivity downtime. The technology offers a paradigm shift and sets a new benchmark for rotovaps without the use of glycol, dry ice, or water, thus eliminating the major sources of material waste associated with conventional rotovaps.

Designed for process scientists on a budget who cannot sacrifice quality, the EcoChyll® X5 is an extremely

efficient alternative to all existing evaporative technologies. Compared to 20 L rotary evaporators from major

manufacturers, the EcoChyll X5 provides over twice the capacity at a substantially lower cost. The patented

direct cooling technology, direct heat, and stirred evaporation flask all contribute to dramatically lower energy

consumption, without requiring a drop of glycol or other coolant fluid, significantly reducing your operating

costs while increasing your recovery rates.

With a true 22 L capacity and a small footprint, it is a premium compromise between cost and convenience.

Our cost-competitive evaporator comes as a turn-key solution for solvent recovery and decarboxylation. The

EcoChyll® X5 automates the vapor cooling process to free-up user time for other operations, while reducing run

time due to faster evaporation rates and significantly shorter start-up time. This method is now the preferred

solution for evaporation in a wide range of botanical extraction applications.

Features :

- Available in 12 L and 22 L

- Recovers all residual solvents (below 500ppm)

- Designed to handle an extremely wide range of solvents, including water and all common solvents used in the cannabis and hemp industries

- No need to move glassware: The stationary evaporation flask is filled with a siphon feed valve and emptied with a drain valve for uninterrupted operation

- Can be incorporated in-line with botanical extraction or winterization systems and fully automated

- Digital interfaces and data monitoring for stirring rod, vacuum pump, chiller, and heating mantle

- Patented EcoChyll condensation unit reaches -40°C on the coils in under one minute

- Spacious evaporation flask prevents “bumping” of solution into condensation unit

- Single user operation with minimal interference required

- Capable of evaporating ethanol at low temperatures (38C)

- Extremely energy efficient

- Safety features for automatic shutdown