Data Storage & Sampling Features of Mini APC

1. Data Storage Features

The Mini APC is equipped with a powerful data storage system, ensuring easy retrieval, analysis, and security of information during air quality monitoring.

- Large Storage Capacity:

- Can store up to 5 million sample records.

- Supports 20,000 zones and 200,000 sampling locations.

- Data Security & Integrity:

- Multi-level authority management, including administrator, supervisor, and operator roles.

- Audit Trail logs ensure data integrity and prevent unauthorized modifications, complying with FDA 21 CFR Part 11.

- Easy Data Retrieval & Export:

- Data can be exported in PDF and database (.db) files.

- Reports generated according to ISO, EU GMP, Chinese GMP, and Fed Std standards.

- Multiple connectivity options, including USB, WIFI, RJ45 (Ethernet), and SENSOR-HUB, for fast data transmission.

- Smart Reporting System:

- Summarizes data by zone.

- Converts measurement units between #/ft³ and #/m³.

- Automatically calculates Upper Confidence Limit (UCL) values and average values.

- Allows precise search by time, zone, and operator.

2. Sampling Features

The Mini APC is equipped with advanced sampling capabilities, optimizing measurement performance and accuracy.

- Multiple Sampling Modes:

- Manual Mode: Allows users to perform sampling manually.

- Automatic Mode: Enables scheduled sampling operations.

- Alarm Mode: Triggers audible and visual alerts when particle concentration exceeds set thresholds.

- Flexible Sampling Time:

- Configurable from 1 second to 168 hours, supporting continuous or periodic monitoring.

- Allows up to 1,000 measurements at a single location.

- Real-time Concentration Curves:

- Displays graphical trends of airborne particle concentration over time.

- Helps in identifying patterns and potential air quality issues.

- High Performance & Stability:

- Mass Flowmeter technology ensures accurate airflow measurement with a ±5% precision.

- PID Controller automatically adjusts blower speed, stabilizing airflow within 100ms.

- Pre-set Sampling Configurations:

- Users can create and save multiple customized sampling schemes for different zones, reducing setup time for repeated measurements.

- Configurations can be backed up and transferred to other Mini APC units via USB.

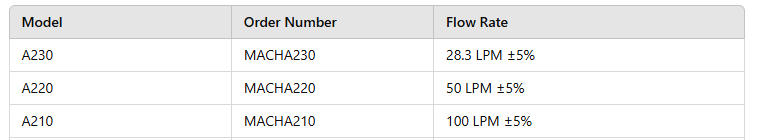

Technical Specifications of Mini APC Models

Particle Size Detection Range

- A220 & A230: 0.3μm – 25μm

- A210: 0.5μm – 25μm

Particle Size Channels

- A210: 0.5, 1.0, 2.0, 3.0, 5.0, 10.0μm

- A220: 0.3, 0.5, 1.0, 3.0, 5.0, 10.0μm

- A230: 0.3, 0.5, 1.0, 3.0, 5.0, 10.0μm

Count Efficiency

- A210: 50% ±20% for 0.5μm, 100% ±10% for >0.75μm (Complies with ISO 21501-4:2018 & JIS B9921:2010)

- A220: 50% ±20% for 0.3μm, 100% ±10% for >0.45μm (Complies with ISO 21501-4:2018 & JIS B9921:2010)

- A230: 50% ±20% for 0.3μm, 100% ±10% for >0.45μm (Complies with ISO 21501-4:2018 & JIS B9921:2010)

Specifications:

- FLOW RATE: 100LPM±5%

- SIZE RANGE: 0.5µm-25µm

- SIZE CHANNELS: 0.5µm, 1.0µm, 2.0µm, 3.0µm, 5.0µm, 10.0µm

- SIZE RESOLUTION: <15% @ 0.5µm (meets ISO 21501-4)

- COUNT EFFICIENCY:50% ±20% for 0.5µm, 100% ±10% for >0.75µm (meets ISO 21501-4 and JIS B9921)

- CONCENTRATION LIMIT:560,000 particles/ft³ at 10% coincidence loss

- ZERO COUNT:<1count/5min

- EXHAUST:Internal HEPA filter (>99.999%@0.3µm)

- ZONE/ LOCATION:20,000 zones and 200,000 locations

- SAMPLING TIME:1 second to 168 hours

- CYCLES:1 – 1000 samples on one location

- LASER SOURCE:Long life laser

- DATA STORAGE:2.5GB, 5,000,000 sets of sample records

- DISPLAY:8” LCD capacitive touch screen

- LANGUAGE:Chinese, English

- DATA RELIABILITY:Compliant with 21 CFR Part 11

- REPORTS: Compliant with ISO/EU GMP/CHINESE GMP/Fed Std

- CALIBRATION FREQUENCY: Recommend once a year

- DIMENSIONS (H X W X D) 9.37 x 6.69 x 8.66 in, 238 x 170 x 220 mm

- WEIGHT: 4.2Kg (9.26lbs) (without battery); 5.2Kg (11.46lbs) (with 2 batteries)

- ENCLOSURE: 316L Stainless SteelPOWER: AC 100-240V, 50 Hz/60 Hz

- BATTERY: 10.8V, 9000mAhx2, rechargeable lithium battery

- BATTERY ENDURANCE: running for 4 hours

- MAX POWER CONSUMPTION: AC 90W

- OPERATING CONDITIONS: 5-35℃ (41-95℉), 5-90%RH non-condensing

- STORAGE CONDITIONS: 0-40℃ (32-104℉), 5-95%RH non-condensing

- SAFETY: EN 61010-1:2010+A1:2019, EN 61326-1:2013, EN 61326-2-2:2013, EN 60825-1:2014, EN 61000-6-1:2007, EN 61000-6-3:2007+A1, FCC Part 15, Subpart B

- WARRANTY: 24 months (after activition or 6 months from ex-factory, whichever comes first)