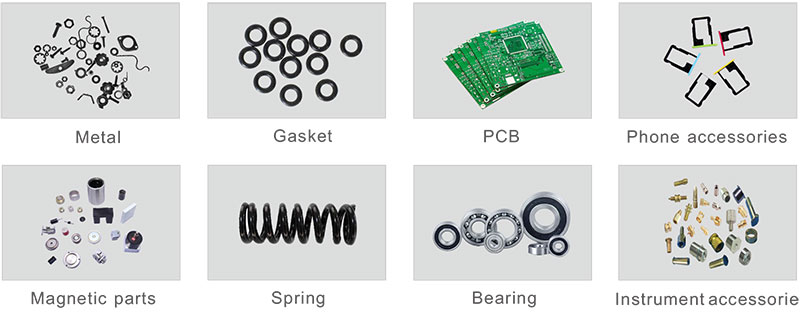

Berdasarkan prinsip pengukuran visual dengan algoritma analisis citra presisi, serta dilengkapi dengan lensa optik telecentric ganda yang memiliki kedalaman bidang tinggi, seri Flash Measuring Machines VX3000 memungkinkan pengukuran dimensi secara cepat hanya dengan satu tombol. Seri VX3000 cocok untuk pengukuran dimensi presisi di berbagai bidang seperti mesin, elektronik, cetakan, injeksi plastik, perangkat keras, karet, peralatan listrik tegangan rendah, bahan magnetik, stamping presisi, konektor, terminal, ponsel, peralatan rumah tangga, papan sirkuit cetak, peralatan medis, jam tangan, alat pemotong, dan lainnya.

Berdasarkan prinsip pengukuran visual dengan algoritma analisis citra presisi, serta dilengkapi dengan lensa optik telecentric ganda yang memiliki kedalaman bidang tinggi, seri Flash Measuring Machines VX3000 memungkinkan pengukuran dimensi secara cepat hanya dengan satu tombol. Seri VX3000 cocok untuk pengukuran dimensi presisi di berbagai bidang seperti mesin, elektronik, cetakan, injeksi plastik, perangkat keras, karet, peralatan listrik tegangan rendah, bahan magnetik, stamping presisi, konektor, terminal, ponsel, peralatan rumah tangga, papan sirkuit cetak, peralatan medis, jam tangan, alat pemotong, dan lainnya.

Parameter

| Model No. | VX3200D | ||

| Image Senor | 5M CMOS | ||

| Monitor | Built-in | 10.4″ LCD (XGA:1024×768) | |

| Outside | 24″ LCD (XGA:1920×1080) | ||

| Acceptance Lens | Double Telecentric Lens | ||

| Light | Ring Light | Four-segment illumination(White Light) | |

| Back Light | Telecentric transmission illumination(Green Light) | ||

| Field of View | Large Field | 200×200mm(4 Angles R50) | |

| High precision | 130×130mm | ||

| Resolution | 0.1um | ||

| Repeatability of Image Meas. | Wide Field |

Without Stitching*1 | ±1um |

| With Stitching*2 | ±2um | ||

| High Precision |

Without Stitching*1 | ±0.5um | |

| With Stitching*2 | ±1.5um | ||

| Accuracy of Image Meas. | Wide field |

Without Stitching*1 | ±5um |

| With Stitching*2 | ±(7+0.02L)μm | ||

| High precision |

Without Stitching*1 | ±2um | |

| With Stitching*2 | ±(4+0.02L)μm | ||

| XY Object Table | X Travel range | 110mm | |

| Y Travel range | 110mm | ||

| Loading Capacity | 7.5kg | ||

| Z-Axis Travel range | 75mm(Motorized) | ||

| Size(LxWxH) | 531×386×731mm | ||

| Weight | 49kg | ||

| Input | AC100~240V, 50~60Hz,2A,300W | ||

| Working Environment | Temp.10℃~35℃, Humidity 20%~80%, Vibration<0.002g, Less than 15Hz | ||

Remark:

*1 In the focus position, the environment temperature is +20 °C ± 1.0 °C

*2 In the focus position, the environment temperature is +20 °C ± 1.0 °C, and the load on the table is 2 kg or less; L is the moving range of the table (mm)

*3 Repeatability ±3μm in 80% measuring area *4 The environment temperature is +20 °C ± 1.0 °C, and the load on the table is 2 kg or less; L is the moving range of the table (mm)

Aplikasi

Perangkat lunak VisionX menyediakan hingga 80 alat analisis ekstraksi, termasuk [Ekstraksi Fitur] (seperti titik maksimum, garis tengah, busur, puncak, dll.), [Alat Tambahan] (seperti titik, garis, dan lingkaran bebas, garis lurus hasil aproksimasi, lingkaran aproksimasi, garis singgung, lingkaran dalam, dll.), [Pelabelan Cerdas], [Toleransi Bentuk], serta [Alat Aplikasi Khusus] (seperti jarak pitch, sudut pitch, slot, ulir, silang bundar, sudut menurun, sudut membulat, dll.).

Hasil pengukuran dan nilai statistik utamanya (seperti rata-rata, σ, 3σ, 6σ, Ca, Cp, Cpk, dll.) akan dicatat dan diarsipkan secara otomatis. Operator dapat memilih berbagai kondisi penyaringan untuk ekstraksi data historis.

Statistik

Grafik tren menampilkan pola perubahan nilai hasil pengukuran secara berkala, seperti perubahan monoton dan periodik, yang dapat digunakan untuk memantau ketidakwajaran dalam proses produksi pada peralatan produksi. Dengan mencerminkan status dan distribusi fluktuasi kualitas produk, histogram dapat secara intuitif menunjukkan informasi mengenai kondisi kualitas dalam proses produksi, yang berguna untuk memprediksi kualitas produk dan tingkat kegagalan.

Melalui diagnosis dan analisis kualitas dengan metode statistik, SPC (Statistical Process Control) dapat memantau kualitas produk dan tren perubahan dalam proses produksi. Dengan menggunakan SPC, solusi pencegahan dalam proses produksi dapat ditemukan, sehingga inspeksi dan perbaikan di tahap selanjutnya dapat dikurangi. Dengan demikian, pengendalian proses produksi dan peningkatan kualitas produk dapat tercapai.

Aplikasi Lainnya